News Excerpt:

Union Minister for Power and New and Renewable Energy (NRE) recently presided over a high-profile meeting to review the results of a study conducted by IIT-Delhi on ambient atmospheric sulphur dioxide (SO2) concentrations and the effect of installing flue gas desulphurisation (FGD) technology on SO2 emissions in various categories of cities.

|

Some findings of IIT-Delhi on ambient atmospheric SO2 concentration and impact of FGD installation in different categories of industries. |

|||

|

Parameter |

Category 1 cities (without TPP) |

Category 2 cities (TPP without FGD) |

Category 3 cities (TPP with FGD) |

|

SO2 concentration in ambient air due to TPP emissions |

No effect |

No effect |

No significant difference observed in SO2 ambient air concentration despite FGD |

|

Secondary particulate matter (PM 2.5) from SO2 emissions |

2 +- 2% |

4 +- 1% |

4 +- 2% |

|

Secondary particulate matter (PM 10) from SO2 emissions |

1 +- 1% |

3 +- 1% |

3 +- 1% |

More about News:

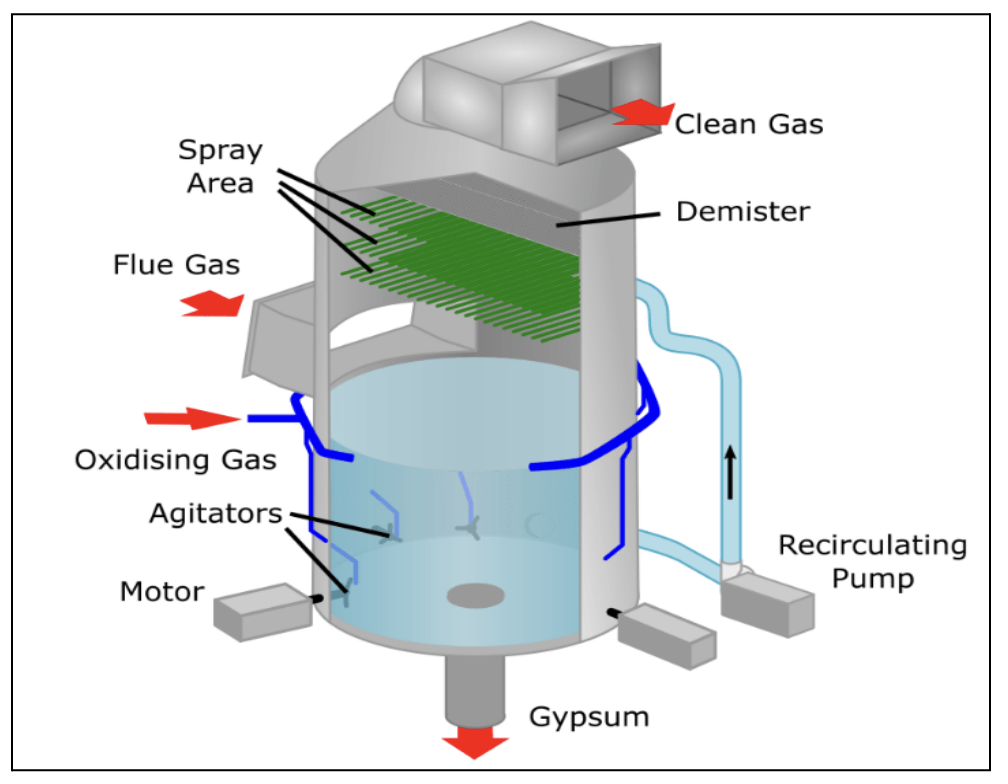

- FGD is the technology used to control sulfur dioxide (SO2) emissions from coal-fired thermal power plants (TPPs).

- The emission standard for SO2 from coal-fired TPPs is acknowledged as the most challenging to meet, largely because FGD technology is expensive and until recently, heavily reliant on imports..

- The technical and financial complexities of FGD installation, as well as related regulatory issues, have been used as reasons to extend the deadlines for complying with the emission norms set by the Ministry of Environment, Forest and Climate Change (MoEF&CC) in 2015.

- The release of these "new findings" from a prominent group doesn't shock those monitoring thermal power plant compliance with emission norms. Government institutions have consistently found reasons to delay implementation as deadlines approach.

- With only a few months left for nearly 19 GW of capacity to meet SO2 standards by December 2024,

- The new study discussed at the meeting has significantly discredited the importance of FGD for TPPs in India.

- An office memorandum detailing the minutes of the meeting was assessed by Delhi-based think tank Centre for Science and Environment (CSE).

- It states that the SO2 emissions from coal-fired TPP stacks have no significant impact on ambient air quality beyond a 60-kilometre radius from the power plant.

- It also disputes the significant formation of secondary particulate matter (both PM 2.5 and PM 10) from SO2 emissions from coal-fired TPPs.

- NTPC, which has awarded contracts for FGD installation covering 93 per cent of its operating capacity and has already installed the technology in three of its plants,

- It opined that FGD operation in power plants could reduce import dependency for gypsum and sulphuric acid.

- The Central Electricity Authority (CEA) stated that the cost of FGD has increased to Rs 1 crore per megawatt (MW), leading to an additional charge of 0.50 paise per unit of electricity if the technology is installed in power plants.

- The article raises concerns about the attempt to "do away" with SO2 norms altogether, questioning the credibility of the MoEF&CC and the Central Pollution Control Board (CPCB) in setting emission standards and the reliability of the National Ambient Air Quality Standards.

- The article criticizes the poor state of environmental governance in the country and questions the silence of environmental regulators (MoEF&CC and CPCB) in a meeting discussing the implementation of standards they had set 8.5 years ago.

Flue-gas desulphurization (FGD)

Dry FGD

Wet FGD

|