Use of Ethanol

Relevance: GS Paper III

Why in News?

Today, ethanol has found its way into a range of applications from its original application as a beverage (wine and beer). It is used as a fuel, a chemical solvent, a disinfectant (hand sanitizer), in pharmaceuticals, cleaning, production of renewable hydrogen, cosmetics, perfumes, and as a feedstock for the production of chemicals.

Applications of Ethanol:

- Fuel: Ethanol is blended with gasoline to create fuels like E10 (10% ethanol, 90% gasoline), E15, and E85. In Brazil, pure ethanol (E100) is used, often selling for less than gasoline.

- Chemical Solvent: Due to its effectiveness in dissolving substances, ethanol is widely used in various industrial and laboratory applications.

- Disinfectant: Ethanol is a key ingredient in hand sanitizers and cleaning products because of its ability to kill germs.

- Pharmaceuticals: It's used in the production of various medications and medical applications.

- Cosmetics and Perfumes: Ethanol acts as a solvent and carrier in the formulation of these products.

- Renewable Hydrogen Production: Ethanol is used as a feedstock for producing hydrogen, which can be used in fuel cells.

- Feedstock for Chemicals: Ethanol is a precursor in the production of various chemicals, particularly ethylene, which is a fundamental building block in the petrochemical industry.

Current demand for Ethanol in various fields:

1. Ethanol in Automotive Fuel

- The blending of ethanol with gasoline began in the 1970s in the U.S., driven by high petroleum prices and the need for a new octane source due to health and environmental concerns over leaded gasoline.

- Ethanol was recognized for its value as a "fuel oxygenate" that helps control carbon monoxide emissions. This led to increased production in the 1980s and 1990s.

- In the U.S., most gasoline today contains at least 10% ethanol. In Brazil, there is a mandatory 27% ethanol blend in gasoline, soon to increase to 30%. Brazilian cars can use blends of up to 100% ethanol.

- Ethanol in fuel reduces toxic emissions, particulate matter (PM2.5), carbon monoxide, nitrogen oxides, and exhaust hydrocarbons, contributing to cleaner air and reducing health risks.

2. Sustainable Aviation Fuel (SAF)

- The aviation sector is a significant contributor to greenhouse gas (GHG) emissions. Sustainable aviation fuel (SAF) is crucial for reducing these emissions.

- Ethanol can be converted into SAF through the Alcohol-to-Jet (ATJ) process, which involves converting ethanol into jet fuel. This process requires 1.7 litres of ethanol to produce 1 litre of SAF.

- The demand for SAF is expected to exceed 18 billion litres by 2030, making ethanol a key resource for meeting this demand.

3. Ethanol in the Chemical Industry

- Ethanol is used to produce ethylene, a core component of the global petrochemical market.

- Ethylene derived from ethanol can replace petrochemical ethylene with no changes required in downstream processes.

- This renewable ethylene has multiple applications, including as a refrigerant and a ripening agent for fruits and vegetables. Using ethanol-derived ethylene saves significant GHG emissions.

4. Ethanol as a Cooking Fuel

- Ethanol is a safer and cleaner alternative to traditional biomass fuels (wood, charcoal, dung, crop residues) used in many parts of the world.

- These traditional fuels produce harmful smoke and pollutants, contributing to approximately 1.3 million premature deaths annually due to indoor air pollution.

- Ethanol does not produce smoke, sparks, or ash, making it a better option for indoor cooking.

Economic and Environmental Benefits

- Domestic Production: Using domestically produced ethanol reduces dependence on imported crude oil, stabilizing fuel prices and enhancing energy security.

- Job Creation: Ethanol production creates jobs in agriculture and other sectors.

- Cleaner Combustion: Ethanol burns cleaner than gasoline, reducing net CO2 emissions and improving air quality.

- Protein Production: Ethanol production from corn yields distillers dried grains with solubles (DDGS), a low-cost protein source for animal feed.

Conclusion

Ethanol's versatility extends beyond its historical use as a beverage. It is a sustainable and renewable resource with numerous applications, from fuel to pharmaceuticals. Ethanol production enhances energy security, creates jobs, and supports environmental sustainability. For countries like India, increasing ethanol use, particularly E100, can significantly contribute to reducing GHG emissions and achieving energy independence. Corn ethanol, in particular, offers additional benefits by providing a cost-effective protein source as a byproduct. Thus, ethanol should be a foundational component of efforts to reduce GHG emissions and transition to renewable energy sources.

|

Beyond Editorial: Challenges regarding Ethanol use in India: While the potential benefits of ethanol use in India are significant, several challenges need to be addressed to fully realise these benefits. These challenges span across production, infrastructure, policy, and public perception. 1. Feedstock Availability and Agricultural Impact

2. Infrastructure and Technology

3. Economic Factors

4. Environmental Concerns

5. Policy and Regulatory Issues

6. Market Dynamics

7. Technical Challenges

Addressing the Challenges: To overcome these challenges, a multi-faceted approach involving government, industry, and consumers is necessary:

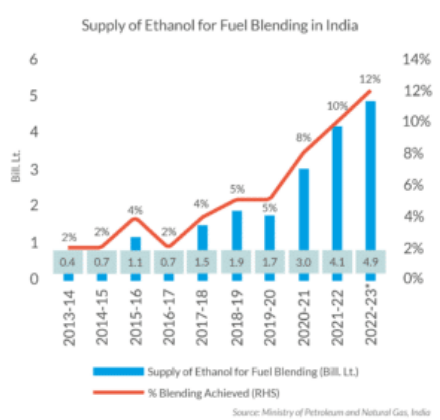

India’s Ethanol Market: Current State

Government incentives

|